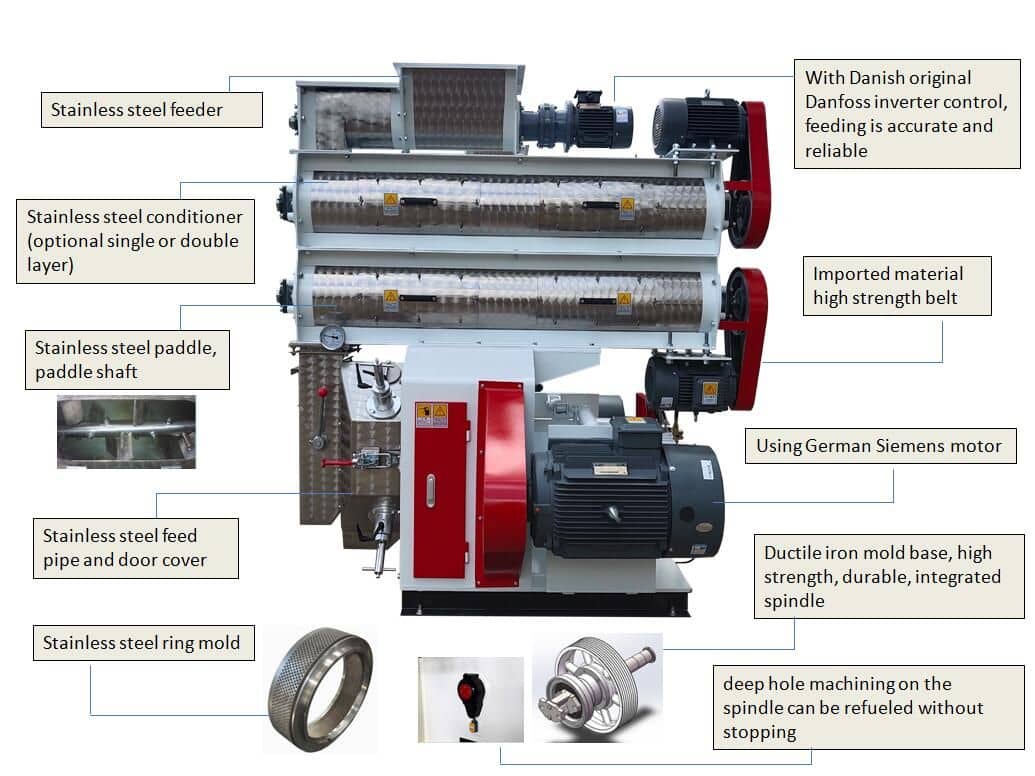

Animal feed pellet mill machine Line 100~1000KG/H

Completed Poultry Feed Pellet Production Line include feed hammer mill, feed mixer, feed pellet machine,cooling machine, packing system. it can make all kinds of animal feed pellet. usually for poultry feed, cattle,cow,sheep, pig. etc. The capacity ranges from 100 kg/h to 10,000 kg/h.