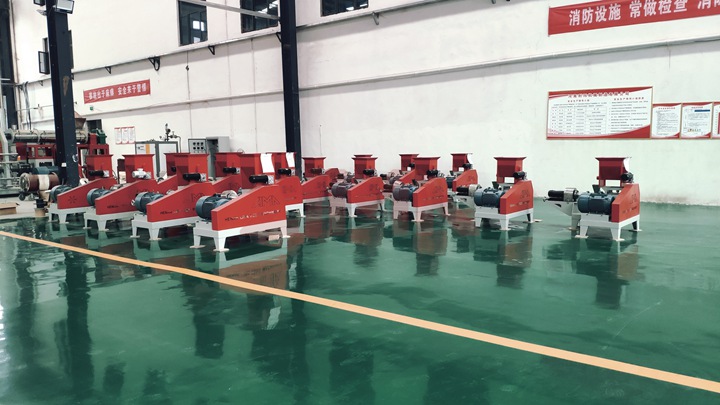

locally made Walleye granulator machine in Zambia

-

small-walleye-feedsmall Walleye feed machine in Zambia-Fishfeedextruders

wet type Walleye feed pellet extruder in Zambia 200KG-5T Wet Type Extruder Fish Feed Pellet Machine Machine Functions. 01. This high efficiency fish feed pellet making machine is widely used for making feedstuff for all kinds of fish. 02. The pellet size from1.5mm to 12mm, fit for different fishes.

Get Price -

.jpg)

wet-type-cargillwet type cargill fish granulator machine in Zambia

Dry-type Granulator; Specification of Dry-type Granulator. 1. Characteristics: 1). No water or alcohol used make possible to avoid producing the unstable granular 2). Saving procedures (wetting, pressing and drying), high efficiency 3). Material are formed after compress and obtains the high density, uniform in weight and no broken tables 4).

Get Price -

.jpg)

walleye-granulatorWalleye granulator machine for the beginner-Fishfeedextruders

Granulator, also popular as crusher or grinder, is size reduction machine used for granulating various materials into small and uniform particle sizes. It is widely used in waste recycling industry, especially in plastic recycling field. Granulator machine is ideal for crushing bulk waste materials such as various scrap plastic products like

Get Price -

granulatorsGranulators | WITTMANN Group

G-Max Beside-the-press Granulators Specifically designed for closed loop recycling of sprues/runners discharged from injection molding machines of up to 400 tons clamping force. G-Max granulators combine energy saving, a compact footprint and a unique damped cutting chamber for significant noise reduction, ensuring a quiet and efficient operation.

Get Price -

.jpg)

locally-madelocally made Walleye granulator machine in South Africa

locally made granulator hen south Africa-Feed Pelleting Machine 10 02 2023 Zerma Africa – Zerma AfricaUnit 1, Barbeque Bend, Corner Dytchley and Hyperion Road, Kyalami, Johannesburg, South Africa +27 11 234 3717 info@zerma.co.za Share Unit 1, Barbeque Be Tel:8619337889051

Get Price -

.jpg)

productsGranulation solutions | GEA Granulators

Granulators. Every Granulation and Drying plant from GEA is a unique union of proven technology and individual solutions. Whether the granulation line is for batch or continuous production, we supply plants for cGMP production configured to meet the customer’s specific requirements. Our granulation and drying plants and process expertise is

Get Price -

engineeringGranulators - an overview | ScienceDirect Topics

These granulators are used for the sizing of plastics, nonferrous metals, heterogeneous materials, and enable to reach controlled output size in the recycling process with the use of classifier screens starting from 2 mm diameter. The size of the granulators ranges between (1060 × 1800) × (1700 × 1800) × (2000) mm; power from 8 to 90 kW

Get Price -

.jpg)

machinesGranulators for plastic recycling – Herbold Meckesheim

Granulators for plastic recycling. Our assorted series of granulators deal with all the key areas of application in post-industrial and post-consumer plastic recycling. They are also used as washing granulators and are fitted with a variety of force feeding devices; wear-resistant, steel-plated special models are also available.

Get Price -

granulatorGranulators | Palamatic Process

The granulator (kibbler) is made of three or four chamfered paddles or scrapper blades mounted on the radius of a 90° drive shaft. As lumps are introduced into the industrial pre-breaker, they are pressed against a screen with a pre-determined mesh size and disintegrate into a more free-flowing, coarse powder.

Get Price